Preparation of thermal sensitive direct printing inks on polyester fabric without chemical pre-treatment

Chunxiao Jiang, Yan Yu , Lun Nie, Xueni Hou, Ruoxin Li*,Guangtao Chang*

College of Textile and Clothing Engineering, Jiang su Engineering Research Center of Textile Dyeing and Printing for Energy Conservation, Discharge Reduction and Cleaner Production(ERC), Soochow University, Suzhou, 215123,State Key Laboratory of Molecular Engineering of Polymers (Fudan University), Shanghai 200438, China, National Innovation Center of Advanced Dyeing and Finishing Technology, Tai'an, Shandong 271000, China

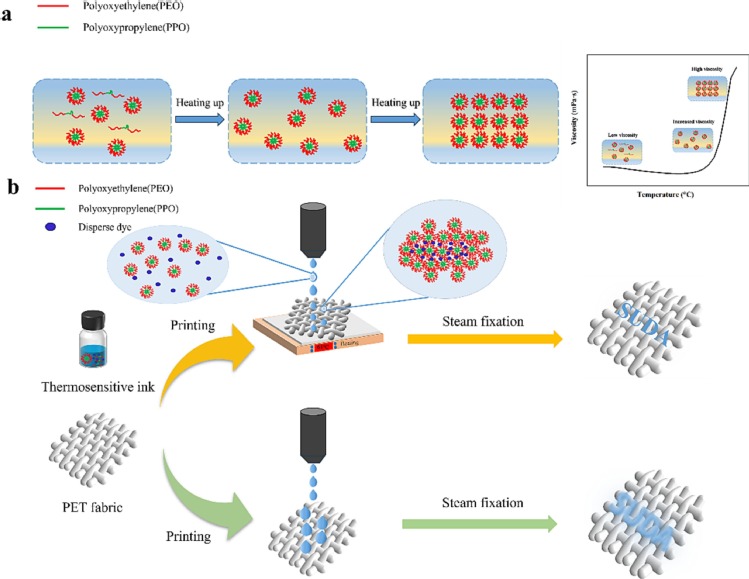

A novel high-temperature disperse dye-based ink, designed for direct digital printing on fabrics, has been developed to eliminate the need for chemical pre-treatment. This innovative ink utilizes a temperature viscosity response mechanism and incorporates a new thermosensitive dye, enabling direct printing on polyester fabrics without pre-chemical treatment. The key to its temperature viscosity response properties is the addition of the nonionic surfactant L64 (poly(ethylene oxide)-poly(propylene oxide)-poly(ethylene oxide) PEO-PPO-PEO). Extensive evaluations of its physicochemical properties, including viscosity, conductivity, pH, surface tension, particle size, and inkjet droplet formation, have confirmed the ink's superior sprayability and overall quality. Notably, when applied to polyester fabric, this ink enhances print clarity and pattern quality while ensuring robust color fastness to rubbing and washing, all without requiring fabric pre-treatment. Furthermore, a comparative analysis of the hand feel between fabrics printed with this ink and unprinted fabrics underscores the minimal impact of the printing process on the fabric's texture. This new type of thermosensitive ink application can effectively reduce the dependence of textile printing fabrics on chemical pretreatment, and effectively reduce the use of water resources in the printing process.

https://doi.org/10.1016/j.porgcoat.2024.108310